Energy consumption reduction in buildings by means of model predictive control

20.8.2021

Almost 40% of the world's total energy consumption is accounted for by buildings – this mostly has to do with heating and cooling – and this ranks them among the largest consumers, along with industry and transport. Contemporary construction methods and modern materials make way for significantly lower energy consumption in newly built and renovated buildings. However, this is not the only way to reduce energy consumption in buildings.

In cooperation with the Faculty of Electrical Engineering and Computing at the University of Zagreb, the company Klimaoprema has launched the project “PC-ATE Buildings” (The development of model predictive control and autonomous energy trading system in the building, project KK.01.2.1.01.0069), co-financed by the EU, which develops a “smarter” control method in buildings based on model predictive control (MPC). This control method is recognized as one of the most applicable solutions for improving energy efficiency in buildings. The current energy conservation achieved by this method in the simulation environment goes as high as 70%, while the experimentally confirmed conservation ranges from 5% to 63%.

Unlike the classical temperature control method in building zones that is based on local control loops and only uses current local measurements of the considered zone, MPC coordinates the operation of all building subsystems, from those responsible for managing heat consumption across zones to those at the building energy distribution level or so-called micronetworks of the building.

Simply put, the MPC is divided into 4 parts:

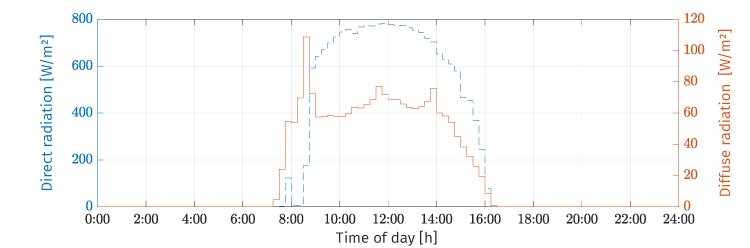

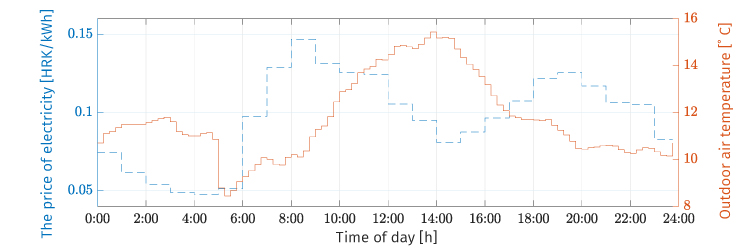

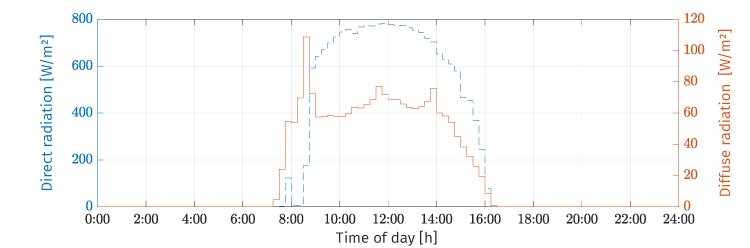

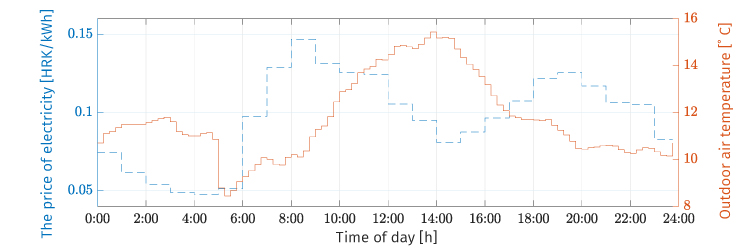

The lower two graphs represent some of the input data that MPC uses for control (prediction of solar radiation, outside air temperature and electricity prices).

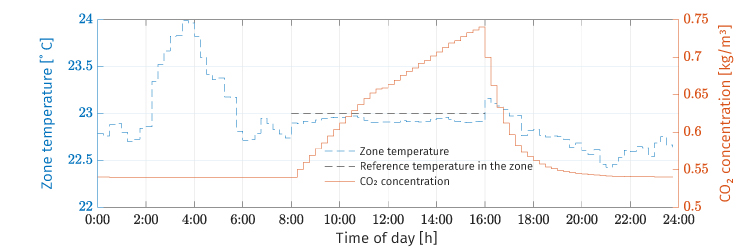

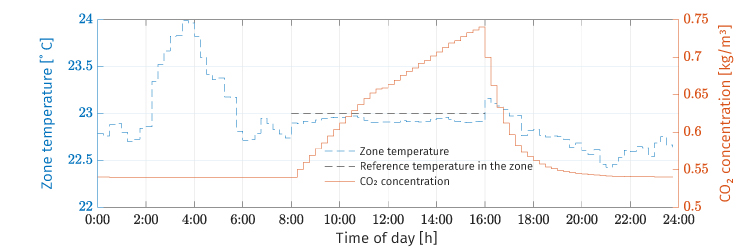

During the period of lower electricity prices (through the night and in the morning), MPC overheats the space exactly as much as necessary so that, with the predicted solar radiation, the air temperature in the zone is within the default comfort during operating hours. The reference operating temperature is set at 23°C.

The further possibilities to which MPC opens the door when it comes to buildings are of utmost importance, given that, by means of MPC, the building flexibly changes its consumption in accordance with the external conditions of prices and energy exchange with the network, in an optimal way for the building. These include the possibility for a building to provide demand-response ancillary services to different entities in the energy system, as well as the possibility for buildings to trade energy or obligations to provide ancillary services with each other. Both of these possibilities can be combined very efficiently under the auspices of aggregators of flexibility of a large number of buildings.

This control method has been implemented in only a few buildings as part of the scientific research of the Faculty of Electrical Engineering and Computing team, where energy conservation varies between 5% and 63%, depending on the comprehensiveness of the installation and the scope of demand-response ancillary services. MPC as a finished good is developed in Klimaoprema in the KOER department. As part of the PC-ATE Buildings project, the verification of the MPC equipment will be carried out at the Klimaoprema headquarters in Gradna.

In cooperation with the Faculty of Electrical Engineering and Computing at the University of Zagreb, the company Klimaoprema has launched the project “PC-ATE Buildings” (The development of model predictive control and autonomous energy trading system in the building, project KK.01.2.1.01.0069), co-financed by the EU, which develops a “smarter” control method in buildings based on model predictive control (MPC). This control method is recognized as one of the most applicable solutions for improving energy efficiency in buildings. The current energy conservation achieved by this method in the simulation environment goes as high as 70%, while the experimentally confirmed conservation ranges from 5% to 63%.

Unlike the classical temperature control method in building zones that is based on local control loops and only uses current local measurements of the considered zone, MPC coordinates the operation of all building subsystems, from those responsible for managing heat consumption across zones to those at the building energy distribution level or so-called micronetworks of the building.

Simply put, the MPC is divided into 4 parts:

- MPC Zone – zone-level optimization

- MPC HVAC – optimization of the system that prepares and distributes the medium for energy transfer for heating or cooling to all zones (e.g. air handler)

- MPC Microgrid – optimization of the building signature at the junction with the energy distribution networks

- Interface modules – functions that convert the outputs from MPC into actuated signals for individual controlled elements.

The lower two graphs represent some of the input data that MPC uses for control (prediction of solar radiation, outside air temperature and electricity prices).

During the period of lower electricity prices (through the night and in the morning), MPC overheats the space exactly as much as necessary so that, with the predicted solar radiation, the air temperature in the zone is within the default comfort during operating hours. The reference operating temperature is set at 23°C.

The further possibilities to which MPC opens the door when it comes to buildings are of utmost importance, given that, by means of MPC, the building flexibly changes its consumption in accordance with the external conditions of prices and energy exchange with the network, in an optimal way for the building. These include the possibility for a building to provide demand-response ancillary services to different entities in the energy system, as well as the possibility for buildings to trade energy or obligations to provide ancillary services with each other. Both of these possibilities can be combined very efficiently under the auspices of aggregators of flexibility of a large number of buildings.

This control method has been implemented in only a few buildings as part of the scientific research of the Faculty of Electrical Engineering and Computing team, where energy conservation varies between 5% and 63%, depending on the comprehensiveness of the installation and the scope of demand-response ancillary services. MPC as a finished good is developed in Klimaoprema in the KOER department. As part of the PC-ATE Buildings project, the verification of the MPC equipment will be carried out at the Klimaoprema headquarters in Gradna.